Nitro technologies

Our best-in-class technical abilities bring you custom designs that combine form and functionality.

At Nitro Technologies, the core focus is the production of catalyst gauzes and customised getter systems. In addition to designing and manufacturing tailored catalyst and customised getter systems, our range of services extend to technical advisory, plant cleaning, refining, and metal management services.

Industries We serve

To support the changeover at the user end from the woven technology, Hindustan Platinum’s nitro technologies division chose to invest in “flat knitting” technology known for its distinct advantages. It allows true tailoring of the catalyst system with variable knitting designs and patterns to match the requirements of our customers’ catalyzed ammonia oxidation processes.

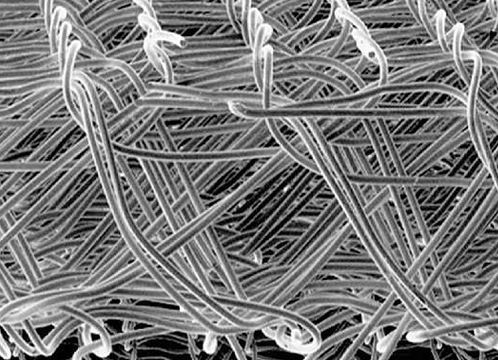

The innovative technology connects weft knit fabrics with the traditional characteristics of warp knit, woven and braided fabrics in both – two and three dimensions.

New technical application opportunities are created, where a knit fabric solution combines form and functionality in one piece. With the flat knitting technology, individual and custom designed products are manufactured in a single part production.

Despite single part production, the flat knitting technology facilitates the reduction of working processes resulting in quicker production times while using minimum material. This inevitably leads to quicker and timely deliveries to our customers.

The flat knitting technology enables us to knit design patterns in both two and three dimensions.

The knitted structure is essentially relevant, since each catalyst gauze layer is exposed to variable operating conditions inside the catalytic converter. When passing through the catalyst gauze pack, the ammonia content in the process gas decreases, while the reaction temperature increases. In addition, other parameters like, the operating pressure, ammonia ratio, feed gas temperature, gauze or the process temperature and the loading of the catalyst vary considerably in the individual processes.

The structure of the catalyst gauze and its wire gauge determines the ammonia conversion, the gauze performance in terms of desired product selectivity, catalyst aging and the primary burn-off loss of the noble metals.

Our knitting technology allows us to optimize the design of the catalyst system for every unique plant process conditions of our customers.

Three-dimensional catalyst gauzes have the advantage of an alternating spatial arrangement of the wires and thus are characterized in a more homogeneous ammonia conversion behaviour as well as higher temperature resistance, while providing a uniform temperature gradient across the catalyst pack.

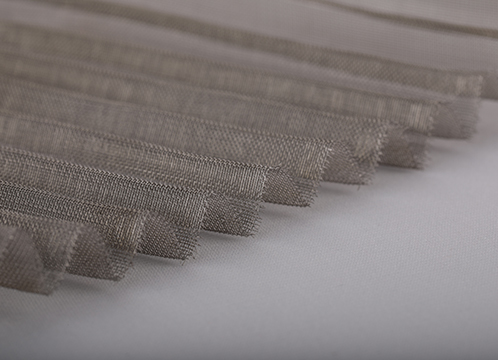

For decades, not much has changed in the structure and the alloy of getter gauzes. They consist of a close-woven fabric made of 95% palladium and 5% nickel alloy. This is surprising, since the getter gauzes recover a great part of platinum and rhodium losses from the catalyst and thus, have the potential to provide a significant contribution to the economics of the overall process.

The lack of interest in technological development in the getter system can be traced back to the parallel, occurring palladium losses, which reduce the efficiency of the getter system significantly. We have understood the nuances in this technological challenge and have focused our efforts on improving and shaping the future of the getter gauze technology.

The use of specific wire thickness and the choice of specific weights of the individual layers of the getter system enable us to achieve significantly higher platinum and palladium recovery rates with reduced palladium loadings. We have channelized our efforts towards the reduction of the palladium losses that critically affect the getter efficiency.

Especially with higher primary burn-off losses, that are mostly associated with the high-pressure plants, an important aspect with the application and efficiency of the getter system can be attributed to the close-woven structure that increasingly becomes obstructed through the alloying of platinum and rhodium and their re-crystallization with palladium.

Flat getter systems in high pressure plants suffer a relatively high pressure drop. For such operating conditions, our corrugated getter gauzes are recommended, which not only help significantly lower the pressure drop due to the specific corrugated (serrated) structure of the getter system, but also provides a much larger surface area for efficient and optimum precious metal recovery.

The Nitro Technologies department determines the performance of the catalyst and the process yield by assessing the environmental condition of every customer’s process. This also includes the quality of the filtration of air and ammonia, or even the fluctuations in the process control.

The start-up procedure affects the development of an active and selective catalyst surface and thus the process yield of the entire campaign. Impurities cause a segregation of platinum and rhodium, which results in rapid aging of the catalyst and an increase in precious metal losses. A control mechanism that regulates the ammonia ratio not optimally matched to the mixed gas temperature prevents high yields.

Each process is characterized by a variety of factors that have a direct impact on the performance of the catalyst and its precious metal losses. To recognize these factors and thus optimize the performance of the catalyst, our products and services are integrated. A combined product-service package system covers the evaluation of the start-up procedure, fault analysis and troubleshooting, and assessment of the control.

Hindustan Platinum’s non-destructive cleaning technology uses process to recover maximum precious metals by water-air based/ chemical/ mechanical methods without affecting the residual life of the equipment.

Non-destructive cleaning has dual benefits to customers:

- Improve efficiency of heat exchangers.

- Derive maximum value from recovered precious metals.

We work in close cooperation with our customers. After carefully studying the plant design and operating parameters, we employ customized and optimal cleaning solutions using plant specific equipment, be it mechanical/ chemical-free based cleaning.

It is important to note that we employ environmental friendly cleaning techniques that cause minimal effect on our ecology.

Since 1997, Hindustan Platinum has been carrying out destructive cleaning of plant equipment to recover precious metals to give maximum metal value credit to its customers.

Hindustan Platinum’s integrated plant facilitates the maximum recovery of the precious metals and provides utmost satisfaction to its customers who depend on our analysis and metal account statement.

Destructive cleaning is a step-by-step process of dismantling and re-sizing the plant in which the flame cutting equipment is involved. All the pieces are chemically treated with liquids to remove 100% of PGM oxides from the steel.

Hindustan Platinum operates one of the world’s most modern precious metals recycling facilities. The precious metals refining provides for comprehensive refining services for catalyst and getter gauze scrap, glass wool filters, precious metals containing dust and sludge from downstream equipment of the ammonia oxidation reactor and storage tank cleaning operations.

Our quality systems are geared towards creating customer satisfaction and are ISO 9001 certified.